What is the correct way to apply thermal gel?

Release time:

2023-04-24

Whenever we apply thermal conductive adhesive on electronic devices, it is always impossible to apply thermal conductive adhesive correctly, because too little information on the application of thermal conductive adhesive leads to poor thermal conductivity of electronic devices, or too little coating leads to lack of thermal conductivity, or Applying too much can cause the thermal paste to spill.

Are you still wondering the right way to use thermal gel?

Whenever we apply thermal conductive adhesive on electronic devices, it is always impossible to apply thermal conductive adhesive correctly, because too little information on the application of thermal conductive adhesive leads to poor thermal conductivity of electronic devices, or too little coating leads to lack of thermal conductivity, or Applying too much can cause the thermal paste to spill.

How does thermal gel work?

Thermally conductive gel with polysiloxane as the main component, supplemented by high thermally conductive fillers, has the properties of non-toxic, odorless, and non-corrosive. Silicone paste fillers are finely ground powders. Silicone oil ensures certain fluidity, and the fillers can be filled The small gap between the CPU and the heat sink must ensure heat conduction, because silicone oil has low sensitivity to temperature, it will not thicken at low temperature, and will not become thinner at high temperature, and it does not use thermal conductive glue to fill the gap between the heater and radiator. To improve the cooling effect.

What are the popular thermal gel application methods in the market today?

Now some people squeeze a little thermal conductive glue on the surface of electronic equipment, and then squeeze the thermal conductive glue with heat sink pressure to apply it. Others use tools, such as scrapers, finger cots, or directly apply it with bare hands. However, if multiple people operate, it is easy to cause It doesn't apply evenly, which causes impurities to cling to it. But now everything is resolved. We sorted out a lot of information about the application of thermal conductive adhesives, and finally screened out the correct application method.

The best way to apply thermal gel:

The main function of thermal conductive adhesive is to fill the gap between the electronic device and the heat sink, so the thinner the coating, the better the effect. Many people think that the more you apply, the better the cooling effect. Electronic devices are coated with thick layers, the thicker the thermal conductivity is, the poorer it is, and air bubbles may appear, which affects thermal conductivity.

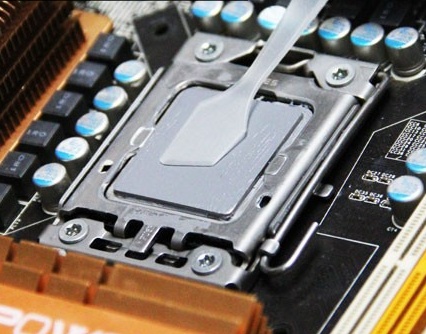

When applying thermal gel, it is best to use a tool to apply it. When operating, apply some thermal paste to the edge of the electronic device, and then use a scraper to spread it evenly in one direction several times, as long as the surface of the processor is evenly covered with thermal paste.

It is best not to apply thermal conductive adhesive by hand, because it is easy to cause uneven application by hand. I believe that no one wants to let their hands be stained with thermal conductive adhesive.

Several ways to apply thermal gel:

1. Five-point method

You can maximize the spread of thermal paste by applying five dots of thermal paste to the electronics and then using the pressure of the heatsink to apply the paste. This method is superior to the single point method.

2. One point method

Put a drop of thermal paste on the center of the electronics and use the pressure of the heatsink to spread it out. This seems to prevent over application of thermal paste. The downside is that the thermal paste doesn't completely cover all the corners.

3. X method

In the center of the electronics, draw x-rays with thermal paste and spread it evenly with the heatsink's pressure. This method ensures that most areas of the electronics are covered with thermal paste.

4. Rotation method

On electronic equipment, use the thermal paste to rotate and squeeze out the thermal paste, and then use the pressure of the radiator to squeeze it out, so that the thermal paste can cover the electronic equipment to the greatest extent. The disadvantage is that it is easy to cause thermal paste to overflow.

5. Apply with applicator

Using a tool such as a thermal paste scraper, card or cardboard as an applicator, apply the thermal paste to all corners, being careful not to allow the thermal paste to seep into other areas.

What should I pay attention to when using thermal gel?

1. Be careful when applying thermal conductive glue. After all, applying thermal conductive glue is still a very delicate job. If you are not careful, the thermal conductive glue may leak out of the electronics, causing the heat dissipation of other unnecessary electronic parts to be covered.

2. It is not good to apply too much, and it is not good to apply too little. If the application of electronic equipment is not thorough, it will affect the overall performance of the thermal conductive gel.

3. To choose a suitable thermal conductive adhesive, the thermal conductive adhesive with too high or too low cohesive force is not good. Only the thermal conductive adhesive with moderate cohesive force is suitable for the coating to exert the best thermal conductivity.

4. Do not buy low-quality thermal adhesives, as the performance of low-quality products cannot be guaranteed.

Why apply thermal gel evenly?

Thermally conductive adhesive is used in electronic equipment, processor heat dissipation, fills the gap between the CPU and the heat sink, and makes the two contact more closely to dissipate heat.

Air is a poor conductor of heat. If the heat sink is not in full contact with the CPU, it will cause poor heat dissipation. Therefore, thermal conductive glue is needed to remove the air. The thermal conductive glue itself has good thermal conductivity, and its function is to assist heat dissipation.

Can Too Much Thermal Gel Damage Electronics?

The heat dissipation from the CPU to the heat sink has to go through many links, because the connection between the middle of the CPU cover and the heat sink is not very tight, so the heat dissipation effect is not very good. Applying thermal conductive glue can effectively solve this problem.

Although thermally conductive adhesive has thermal conductivity, the less thermally conductive adhesive is applied, the better. Thermally conductive gels are actually less conductive than metallic materials, especially when compared to heat sinks made of copper and aluminum.

Therefore, the heat dissipation of electronic equipment is mainly based on metal heat sinks, supplemented by thermally conductive adhesives, so the application of thermally conductive adhesives should be as thin as possible and evenly distributed. After the heat sinks are installed, a pan is required to fully fill the gaps with the thermally conductive adhesive. Make the heat sink conduct heat better.

in conclusion

In the end, we concluded that the best way to apply thermal conductive adhesive so far is to use a tool to apply it. This method can prevent the uneven application of thermal conductive adhesive and the occurrence of water leakage problems.

If you are still applying thermal paste by hand, we strongly recommend that you change this immediately and use tools to apply thermal paste.

In summary, we have come to the conclusion that the best way to apply thermal conductive adhesive is to use tools to apply it, which can prevent uneven application and leakage of thermal conductive adhesive.