How long does the silicone thermal pad last?

Release time:

2023-04-24

With the continuous development of science and technology, there are many kinds of materials used in electronic products, which have a wide range of applications in all aspects. Among them, the silicone thermal conductive sheet is a kind of strong thermal conductivity, good physical inertia filler, will not make the circuit short circuit on the circuit board. Silica gel thermal conductors are generally made of silicon and some metal oxides.

With the continuous development of science and technology, there are many kinds of materials used in electronic products, which have a wide range of applications in all aspects. Among them, the silicone thermal conductive sheet is a kind of strong thermal conductivity, good physical inertia filler, will not make the circuit short circuit on the circuit board. Silica gel thermal conductors are generally made of silicon and some metal oxides.

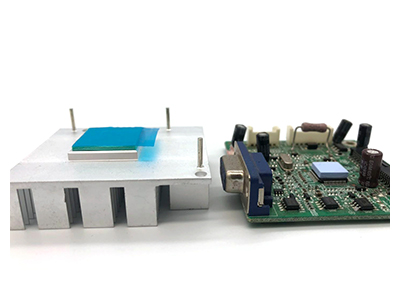

At present, there are many kinds of heat-conducting silicone sheets on the market. Generally speaking, silicone heat conductive sheets are mainly used for electronic products and medical equipment that need heat dissipation. Silicone heat conductive sheet is widely used in the field of heat dissipation of electronic products. Thermal conductive silica gel sheet is mainly based on silicone as the substrate, adding various auxiliary materials such as metal oxides, and then through a special process to synthesize thermal conductive medium materials. In industry, this material is widely used. Also known as thermal conductive silicone pad, thermal conductive silicone sheet, soft thermal conductive pad or thermal conductive silicone gasket.

Silicone heat conductive sheet mainly uses gaps to transfer heat and complete the heat transfer between the heating part and the cooling part. It can also play the role of insulation, shock absorption and sealing, which can realize the miniaturization and ultra-thin design of the equipment.

How to use silicone heat conductive sheet?

Silica gel thermal conductive sheet itself has a certain natural adhesion, it is very convenient to use. When installing, ensure that the two adhesive points are clean. This results in a very strong bond between the thermal grease and the adhesive product.

Almost all thermal silicon wafer products use the same steps, and this method meets the requirements of being fast, simple and easy to use. In addition, according to the size of the place to stick, it is enough to cut the silicone heat conductive sheet properly.

If the silicone thermal conductive sheet can follow the above operating procedures, the service life is generally more than 5 to 10 years. Of course, this is not absolute. The service life of silicone heat conductive sheet will have certain losses because of different manufacturers, so the service life will also change. Affected by these factors, the effective service time is also different.

Silicone thermal conductive sheet to long-term use, need to be properly protected, according to the standard operation, in order to better use of products, thus greatly extending the service life of thermal conductive silicon sheet, reduce the cost.